In the world of retail, the importance of quality and durability in shopping bags cannot be overstated. Reflective shopping bags, in particular, have gained popularity for their safety features and unique aesthetic. However, maintaining high quality in these bags is crucial for customer satisfaction and brand reputation. This blog explores key strategies to enhance the quality of reflective shopping bags.

1. Ensuring High-Quality Ink in Printing

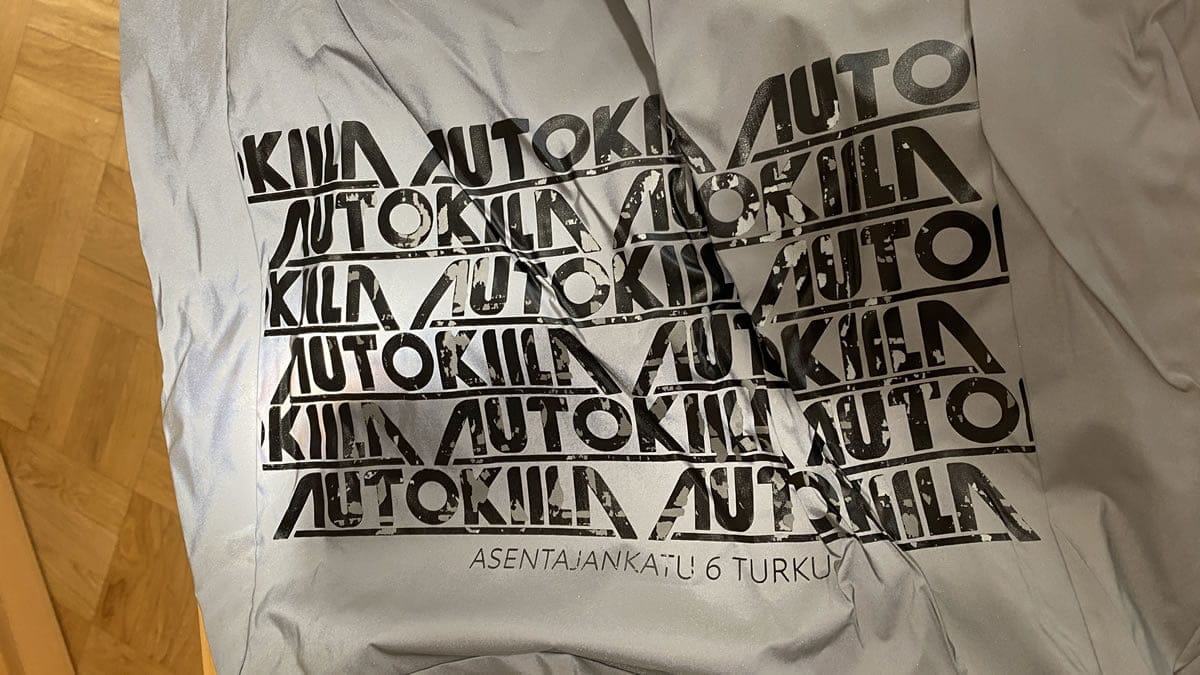

The first aspect of quality control involves the printing process. A common issue encountered is the transfer of ink from the logo of one bag to the surface of another when they are stacked or stored together. This problem is typically caused by the use of inferior inks.

Solution: Reflective Shopping Bags address this, it’s essential to select high-quality, durable inks for printing logos and designs. These inks should have excellent adhesion properties and resistance to smudging or transfer. Additionally, the drying and curing process of the ink should be optimized to ensure that the print is completely set before the bags are packaged or used.

2. Improving the Durability of Bag Handles

Another critical area is the finishing of the strings or handles of the bags. Often, the ends of the strings are not properly sealed, leading to fraying and unravelling, which can cause unpredictable quality issues.

Solution: The solution lies in properly sealing or ‘heat-sealing’ the ends of the strings. This process involves applying heat to the ends, which fuses the fibers together, preventing fraying and ensuring a neat, durable finish. This small but significant step can greatly enhance the overall durability and aesthetic appeal of the bags.

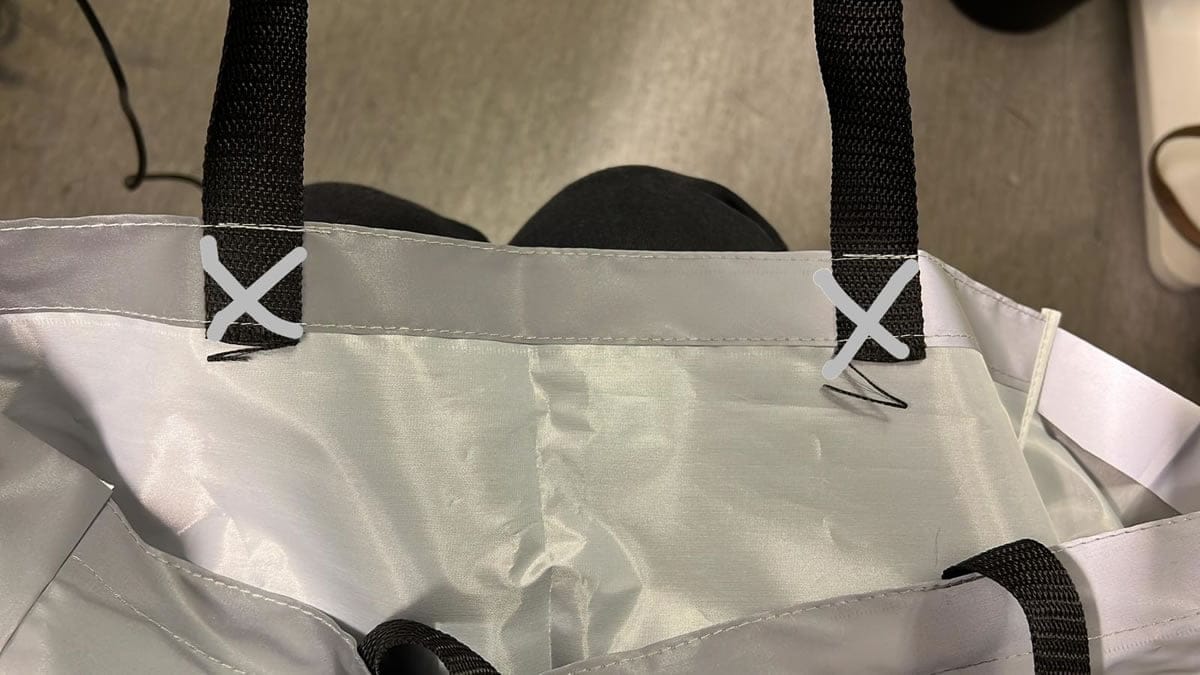

3. Strengthening the Connection Between Straps and Reflective Material

Finally, the method of attaching the straps or handles to the reflective material of the bag plays a vital role in its durability. A weak connection can lead to Reflective Shopping Bags straps detaching under the weight of the bag’s contents, rendering the bag unusable.

Solution: To mitigate this, employing a cross-stitching method at the point where the straps connect to the bag is recommended. Cross-stitching provides a more robust and resilient joint, significantly reducing the likelihood of detachment. This technique not only improves the functionality of the bag but also adds to its visual appeal.

By focusing on these key aspects of quality control – superior ink quality, enhanced handle durability, and robust attachment techniques – manufacturers can significantly improve the longevity and appeal of reflective shopping bags. Such improvements not only enhance the user experience but also reflect positively on the brand’s commitment to quality and sustainability.