Reflective TPU (Thermoplastic Polyurethane) is revolutionizing the world of reflective materials with its unique manufacturing processes and material characteristics. Born from the foundation of TPU film, this innovative material is processed to possess reflective capabilities, combining the worlds of functionality and environmental sustainability. In this blog, we’ll delve into the essence of Reflective TPU, its production techniques, and its growing applications, illuminating the path toward a greener, more reflective future.

Before we learn about the reflective TPU, let’s check first:

What is TPU Material?

Thermoplastic Polyurethane (TPU) is a versatile material known for its application across various industries, such as footwear, automotive components, medical devices, and electronic casings. TPU is characterized by:

- High Elasticity and Flexibility: As an elastomer, TPU offers excellent elasticity, able to return to its original shape after stretching. Its flexibility makes it an ideal material for manufacturing sports shoe soles and phone cases.

- Wear Resistance: TPU’s outstanding wear resistance makes it suitable for applications demanding durability.

- Oil and Fat Resistance: With good resistance to oils, fats, and many chemicals, TPU is ideal for environments that may encounter these substances.

- Temperature Tolerance: TPU maintains stable physical properties across a wide temperature range, enduring both low and high temperatures.

- Eco-friendliness: Being recyclable, TPU minimizes environmental impact, aligning with global sustainability goals.

- Transparency and Colorability: TPU can be produced in transparent forms or various colors, catering to specific aesthetic requirements.

These properties make TPU a preferred material in industries where durability, elasticity, and environmental friendliness are prized.

Reflective TPU: Combining TPU with Reflective Technologies

Reflective TPU transforms the base TPU material into a reflective marvel using two primary manufacturing techniques: micro-prismatic structures and glass bead coating.

Micro-Prismatic Technique

This technique mirrors the method used in reflective PVC by embossing micro-prismatic structures on one side of the TPU film. This structure allows for the application of Reflective TPU in various colors, achieved by incorporating color masterbatches into the TPU material. However, the reflective brightness and transparency are somewhat limited compared to PVC due to material shrinkage after cooling and setting. The reflectivity of this type of Reflective TPU is relatively lower, with white materials having a retroreflective coefficient between 100-200, and darker materials even lower.

Micro-Glass Bead Technique

The second technique uses TPU film as a base, typically 0.5 to 1mm thick, and applies a micro glass bead coating to significantly enhance the reflective effect. This process mirrors that of conventional reflective fabrics, generally producing Reflective TPU films in silver-grey due to the micro glass beads’ color overshadowing the TPU’s. The advantages include high reflective intensity, though the drawbacks are limited color options and the potential wear of the glass bead surface over time.

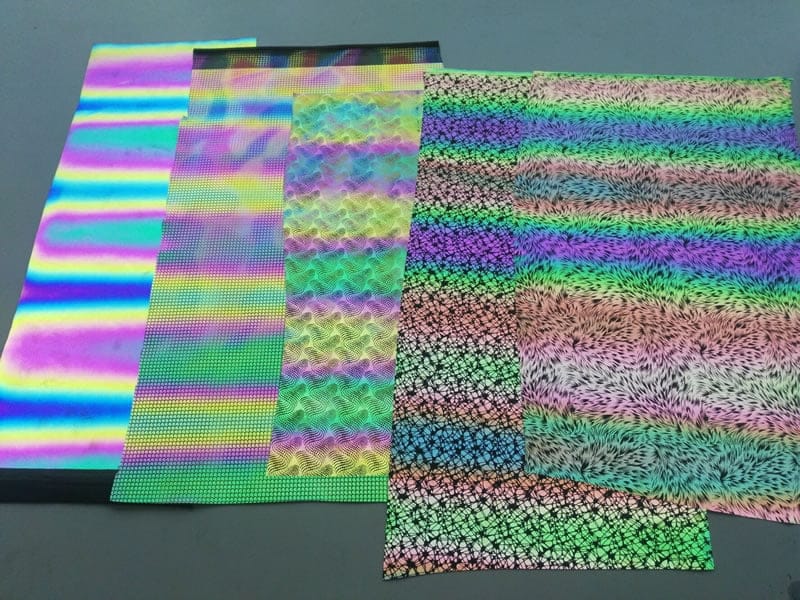

In the same way as to create the rainbow color reflective fabric, we also can get the rainbow color reflective TPU film. it is used on shoes, backpacks, logos, etc.

Applications of Reflective TPU

Reflective TPU finds its place in:

- Reflective pendants and wristbands, falling under reflective accessories.

- Reflective logos on clothing.

- Reflective equipment.

With superior characteristics like fold resistance, soft flexibility, low-temperature tolerance, and eco-friendliness, Reflective TPU is gradually replacing reflective PVC products. This shift is supported by increasing restrictions on PVC products in many countries. Despite its advantages, Reflective TPU has not yet met certain European standards, such as CE EN17353:2020, in reflective intensity, indicating room for improvement in some applications.

Send Inquiry