What Are 3M Reflective Stickers?

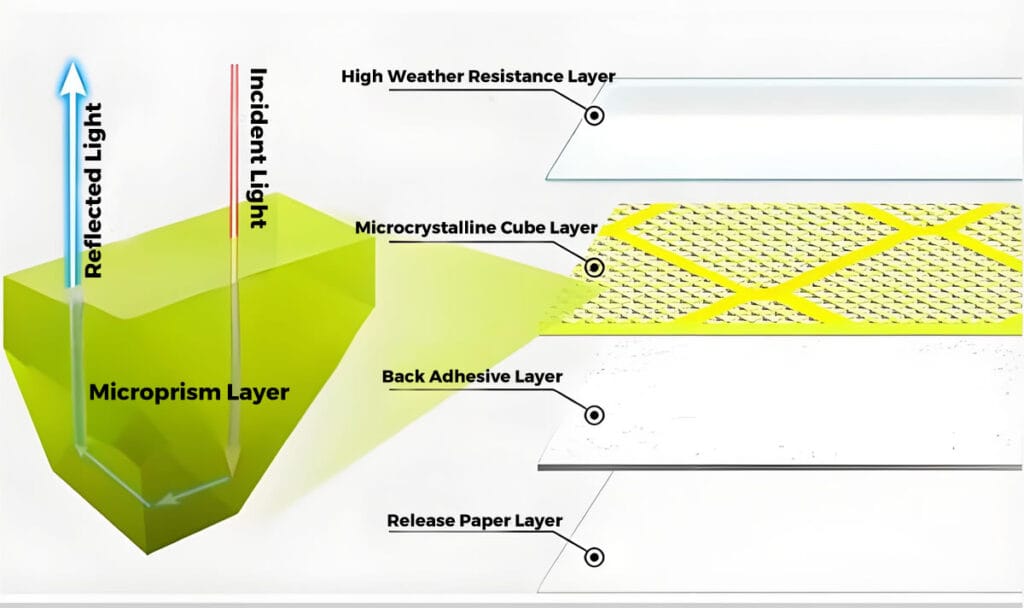

3M reflective stickers are adhesive-backed materials that incorporate retroreflective technology developed by 3M Company. These stickers contain microscopic glass beads or prismatic elements that reflect light directly back to its source, making them highly visible when illuminated by headlights, flashlights, or other light sources in low-light conditions.

How Retroreflective Technology Works

The science behind reflective stickers involves specialized materials that bounce light back toward its origin rather than scattering it in multiple directions. This retroreflective property creates a bright, attention-grabbing effect when light hits the surface, significantly enhancing visibility in darkness or poor weather conditions.

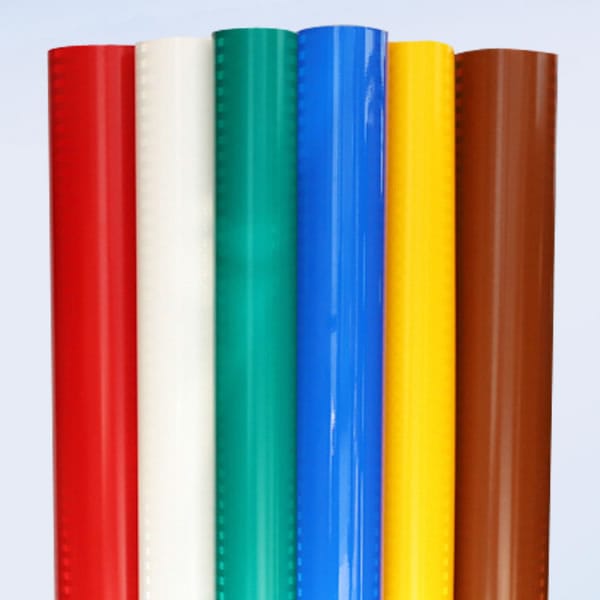

Types of 3M Reflective Materials

3M offers a variety of reflective sheeting types designed for different applications, primarily focused on traffic safety, signage, and visibility. These products use retroreflective technology, which reflects light back to its source (like headlights), enhancing visibility in low-light conditions. For more information, please check 3M official site

Provides basic retroreflectivity suitable for non-critical applications with 5-7 years of outdoor durability

High Intensity Grade

Offers increased brightness and longer distance visibility with 7-10 years of durability

Delivers maximum reflectivity for critical safety applications with 10+ years of durability.

3M reflective fabric, a reflective material with a fabric base in the form of glass microspheres. The back of the material can be laminated with double-sided adhesive to create reflective stickers.

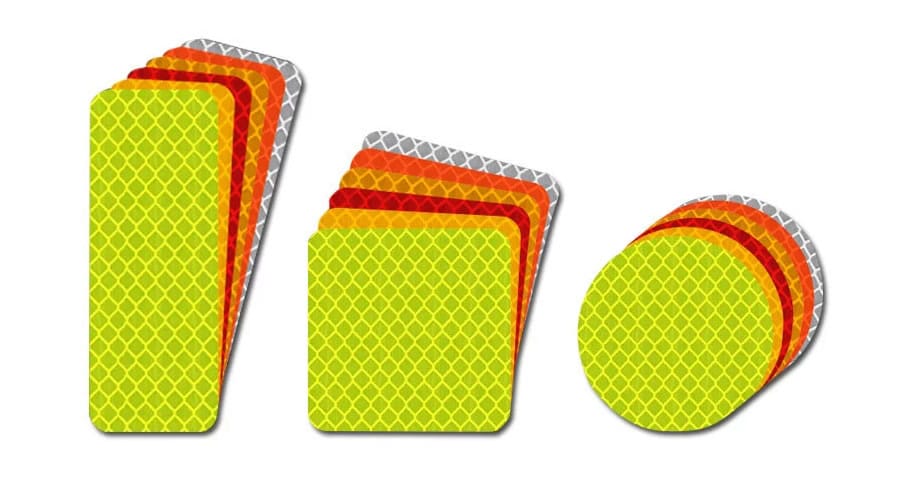

Applications for Custom 3M Reflective Stickers

Vehicle Safety and Identification

3M reflective stickers provide essential visibility for vehicles operating in low-light conditions. Common applications include:

- Fleet vehicle identification markings

- Emergency vehicle markings

- Construction and utility vehicle safety markings

- Delivery vehicle visibility enhancements

- Bicycle and motorcycle safety stickers

These applications help identify vehicles at night while improving overall road safety by making them more visible to other drivers.

Personal Safety Equipment

Reflective stickers enhance the visibility of personal safety gear:

- Hard hat reflective stickers

- Helmet reflective markings

- Backpack and bag safety stickers

- Footwear visibility enhancements

Adding custom reflective elements to personal equipment increases wearer visibility in low-light environments, particularly important for workers in construction, roadwork, or other hazardous settings.

Outdoor and Recreational Uses

Many outdoor enthusiasts and recreational organizations utilize custom reflective stickers for:

- Bicycle frame and helmet markings

- Camping equipment identification

- Trail markers and outdoor signage

- Kayak and canoe visibility

- Running and hiking gear enhancement

These applications help improve safety during dawn, dusk, or nighttime activities while also providing identification for equipment.

Industrial and Workplace Safety

In industrial settings, custom reflective stickers serve critical safety functions:

- Equipment identification in low-light areas

- Emergency exit markings

- Hazard warnings and safety instructions

- Forklift and machinery visibility enhancements

- Warehouse organization and safety systems

Properly placed reflective stickers can prevent accidents and improve operational efficiency in industrial environments.

Promotional and Branding Applications

Beyond safety applications, many organizations use custom reflective stickers for:

- Promotional giveaways with enhanced visibility

- Brand logos with reflective elements

- Event marketing materials with safety benefits

- Retail product packaging enhancements

- Outdoor advertising with nighttime visibility

These marketing applications combine safety benefits with brand visibility, creating dual-purpose promotional materials.

Ordering Custom 3M Reflective Stickers

Specification Requirements

When ordering custom reflective stickers, be prepared to specify:

When ordering custom reflective stickers, be prepared to specify:

- Reflective material grade required

- Dimensions and shape details

- Quantity needed (with consideration for price breaks)

- Color specifications and printing requirements

- Adhesive type appropriate for the application surface

Artwork Preparation

Proper artwork preparation ensures quality results:

- Vector formats preferred for sharp edges and scalability

- Color separation for multi-color designs

- Minimum line thickness guidelines

- Bleed and margin specifications

- Resolution requirements for any raster elements

Prototype and Approval Process

Before full production, consider:

- Sample approval for material and color verification

- Reflectivity testing under intended conditions

- Application testing on actual surfaces

- Durability verification if applicable

- Final design approval process

Production Timeframes

Typical production processes involve:

- Artwork preparation and approval: 1-3 days

- Material cutting and preparation: 1-2 days

- Printing and finishing: 2-5 days

- Quality control inspection: 1 day

- Shipping and delivery: Varies by location

Expedited services may be available for urgent requirements.

Installation and Application Guidelines

Surface Preparation

Proper installation begins with surface preparation:

- Clean the application surface thoroughly

- Remove oils, dust, and contaminants

- Ensure surface is completely dry

- Apply at recommended temperature range

- Consider primer for difficult surfaces

Application Techniques

For optimal adhesion and appearance:

- Use firm pressure with squeegee or roller

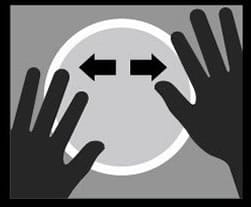

- Apply from center outward to remove air bubbles

- Avoid stretching the material during application

- Allow recommended cure time before exposure

- Follow specific instructions for curved surfaces

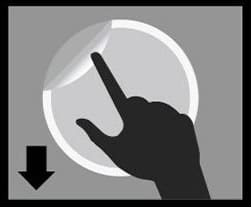

Clean the construction area, ensuring it is free of dust, water marks, oil stains, and rust.

Peel off the backing paper, align the product to the correct position, and stick it on.

After applying, press the reflective sticker firmly to ensure there is no air trapped and it is adhered securely.

Common Application Mistakes

Avoid these common errors:

- Applying to dirty or wet surfaces

- Installation in temperatures outside recommended range

- Stretching or distorting material during application

- Insufficient pressure during application

- Touching adhesive surface before application

Custom 3M reflective stickers represent a versatile, cost-effective solution for enhancing visibility and safety across numerous applications. From vehicle identification to personal safety equipment, these customizable adhesive products combine practical safety benefits with branding opportunities.

When selecting and implementing reflective stickers, consider the specific application requirements, environmental conditions, and desired lifespan to choose appropriate materials and adhesives. Proper design, installation, and maintenance will maximize the effectiveness and longevity of these visibility-enhancing products.

By understanding the options, benefits, and best practices associated with custom reflective stickers, organizations can implement targeted safety solutions while potentially incorporating branding elements for dual-purpose functionality.

For specific requirements or technical questions about custom reflective stickers for your application, consulting with a knowledgeable manufacturer like Yolite can help ensure you select the most appropriate materials and specifications for your needs.